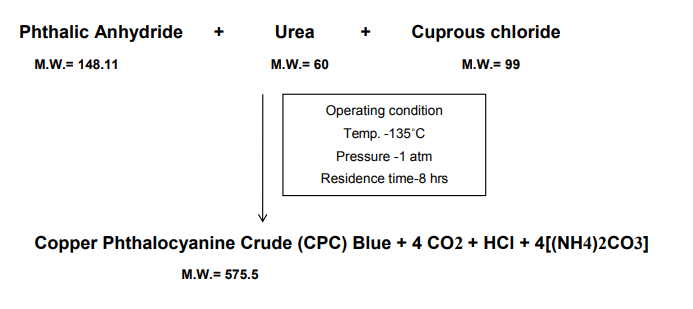

produced by condensing phthalic

anhydride, Cuprous Chloride and Urea in presence of

Ammonium

Molybdate as a catalyst.

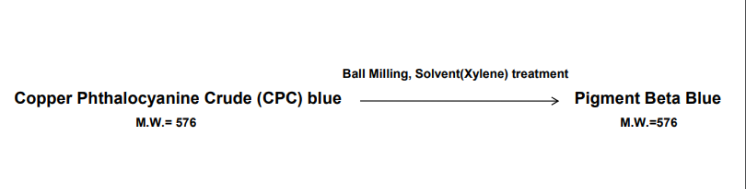

Crude CPC Blue is taken into Ball mill for grinding. Here the particle size of the material gets reduced. Then the grinded material is taken into the reactor with Caustic flakes. Caustic flakes are used to get alkaline pH. The alkaline pH results better dispersion of particles for pigmentation. The mass is refluxed for pigmentation. Here the color of the material gets enhanced due to fine turning with Xylene/IBA.

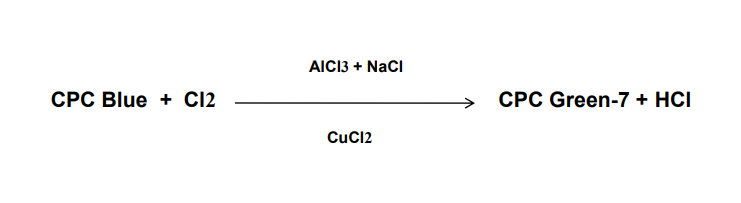

In GLV first charge Aluminum Chloride & Sodium Chloride. Melt this by giving heat through thermic fluid heater after melting is taken place charge Copper Phthalocyanine Blue. This is main raw material for Green-7 product. Pass the chlorine gas with maintaining temperature between 160˚C to 190˚C temperature because this process is exothermic reaction and for that do the cooling through hytherm cooling system for maintaining temperature.